The PowerWave Bus System™ is specifically designed for the critical power market by PowerBar, a leading manufacturer of critical power equipment. With over 30 years serving the data,banking, processing centers and industrial markets, PowerBar has gained an unmatched level of expertise in the development of reliable products for critical power facilities. Through this extensive background and experience, we know that up time

and clean power are critical to our customers and the customers these facilities serve.

Busway systems have been available for years. Most systems applied

to the data center are mere adaptations of industrial or commercial systems that have not been designed for critical power loads. Now, PowerBar has created a robust, elegant bus

system designed specifically for critical power and data center installations.The PowerWave Bus System™ with Toughrail Technology™offers a complete line of fully compatible, continuous opening plug-in busway with all the required fittings to complete your job.The

PowerWave Bus System™is a flexible, easy to install, highly efficient structured busway that safely distributes power for any critical power, industrial, or commercial application. PowerWave Structured Bus™ is a continuous plug-in style rail rated at 160–800 amps with plated copper conductor and contacts. The patented PowerWave Toughrail Technology™ systems are available in the following configurations:

• three-pole and four-pole

•optional 150% fully rated neutral

• optional 100% rated isolated ground

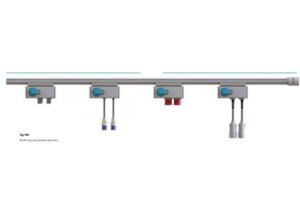

Rugged & Compact-The PowerWave Bus System™ with Toughrail Technology™structured

bus system is a rugged, yet compact system that eliminates any need for floor space, maximizing your server installation area. Our unique Tough rail Technology™ integrates Power and communication in a single run, enhancing load communications, and reducing The space required compared to multiple cable and conduit runs.

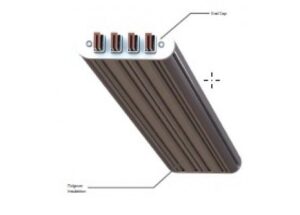

Construction and Finish- PowerWave Toughrail Technology™system housing is created from a single piece aluminum extrusion with a black anodized finish which enhances the dissipation of heat along the bus, reducing any hot spot concentrations. With optional finish

colors to meet your needs, the PowerWave Bus System™with Toughrail Technology™ is aesthetically pleasing and can enhance the look of your installation.The insulation used in the PowerWave Toughrail Technology™system is manufactured with a Class C rated (149°C/300°F) material.The insulation wraps around each bus bar,giving perfect separation from phase-to-phase and phase-to-ground while enhancing the short circuit rating.

Plating-To improve system conductivity and reduce resistance, the PowerWave Bus System™ is only available with nickel-plated copper bus bars. This proven system mproves the overall contact surface, reducing surface to surface resistance, and resisting corrosion in high humidity environments.PowerWave™

Integral Ground Path- PowerWave Toughrail Technology™ incorporates an integral around system – a feature of its extruded, one-piece aluminum housing. By utilizing the housing design for the grounding system we ensure the path, improve the capacity, and

encase the complete system.Short Circuit Strength PowerWave Toughrail Technology™ system’s unique design for low voltage distribution from 160-800 amps achieves an AIC rating for unprotected bus at 22,000 RMS symmetrical.Our testing was completed and certified by an independent third party.

Voltage Drop-PowerWave Toughrail Technology™ incorporates a low-loss design

generating one of the lowest voltage drop ratings in the industry.Low resistance is a key design criterion for power quality equipment in the critical power and data markets.

Recycle– PowerWave Bus System™gives you a highly recyclable and configurable system installation in your facility. From the simplest component to the most complex electrical

infrastructure, PDI can help you at the beginning and the end of your project.

Energy efficient- The potential for substantial energy savings is created by the patented

design of the PowerWave Bus System™:

•Distributed bus eliminates energy-wasting hot spots from the data center due to electrical cable congestion.

• Distributed bus has less voltage drop then conventional wiring methods allowing for moreefficient use of energy consumption.

• Distributed bus reduces the foot print allocated to electrical systems in your

facility, allowing you to make power infrastructure sizing more accurate.

• Distributed bus enhances your power factor rating due to the low line-to-line

voltage loss.

Safe- Non Toxic: All components of the PowerWave Bus System™ are strictly made in accordance with all standards to eliminate any toxicity in case of a fire in your facility.Non

Propagating: If a fire occurs in your facility,PowerWave

Bus System™ is self extinguishing and will not propagate the flame.

Intelligent- Communication bus is integrated into system housing.

• Communication runs to all distribution power.

• High level data accumulation.

• Complete integrated communications control with PowerBar.

Full range of Elbows, Cross Sections and Tees.

Every intricate part can have a reversed neutral position,

isolated ground and or a 150% neutral.

Mounting components are attached to our TOUGHRAIL™ technology

Communication capability can be added for each device with transitions through any of the system components. (factory assembled)

All the parts you need for any possible configuration.

Custom finish available (optional)

Communication rail incorporated into design allowing for factory istallation of communication cable to manage your tap devices.

Consultancy, deployment and on-site assistance. Maintenance services. Remote monitoring with 24×7 NOC